Space@Sea – Final Demonstration of the Modular Floating Island with Superstructures Manufactured at DST

With the Horizon2020 project completing this month, the final demonstrator was presented at the Maritime Research Institute Netherlands (MARIN). At DST the superstructure to represent the results of two substantial work packages (WPs) has been designed and manufactured.

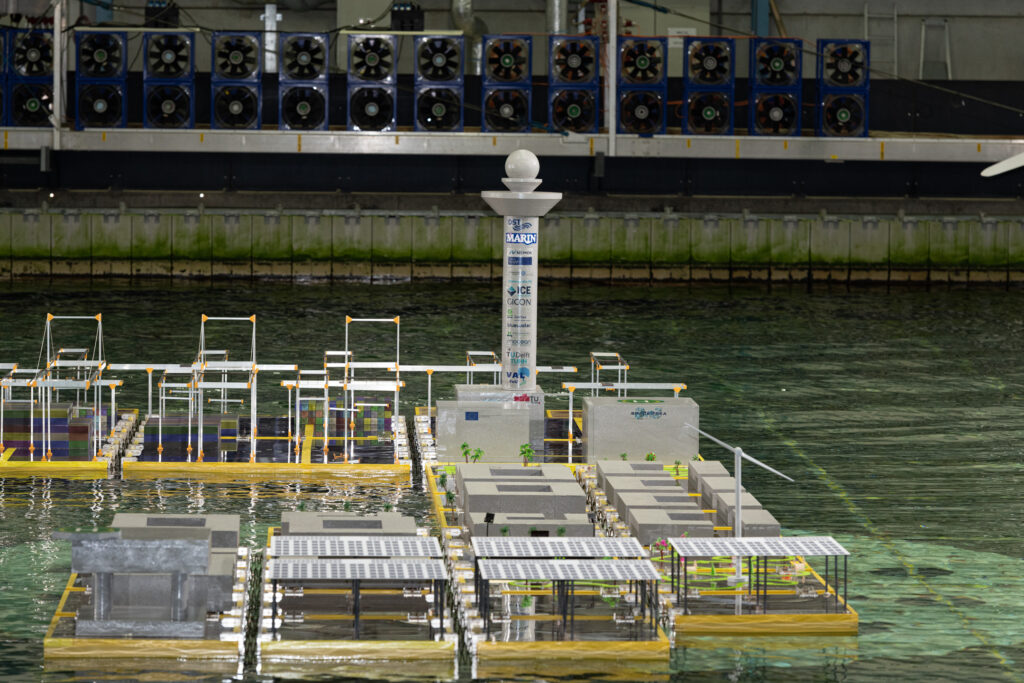

Part of the Space@Sea demonstrator island with modules hosting the applications of energy conversion (in the front), living and transport & logistics (in the back) at a model scale of 1:60 (Courtesy by MARIN)

The Space@Sea project initiated the design of affordable and reliable deck space for multiple activities at the open ocean. Built at scale, multiple floaters were assembled to form one large island. Individual floaters do fulfil different purposes, e. g. farming applications, living of humans at sea, energy harvesting and transport & logistic operations.

Within WP9, a Transport&Logistics hub to handle containers has been developed to offer solutions for the expansion of coastal ports that is limited to land scarcity. Three sizes and two types of cranes were built from 3D-printed connectors and rectangular aluminium tubes to demonstrate the floating container terminal. This combination ensured an efficient production profiting from carry-over parts. Rail Mounted Gantry (RMG) or Ship to Shore (STS) cranes were assembled from this set of parts. Each crane was equipped with an assembly of a trolley and spreader to illustrate the concept of an automated container terminal. In total, DST manufactured and provided 56 RMG and 12 STS cranes which are foreseen to handle about 12000 TEU/day (in full scale).

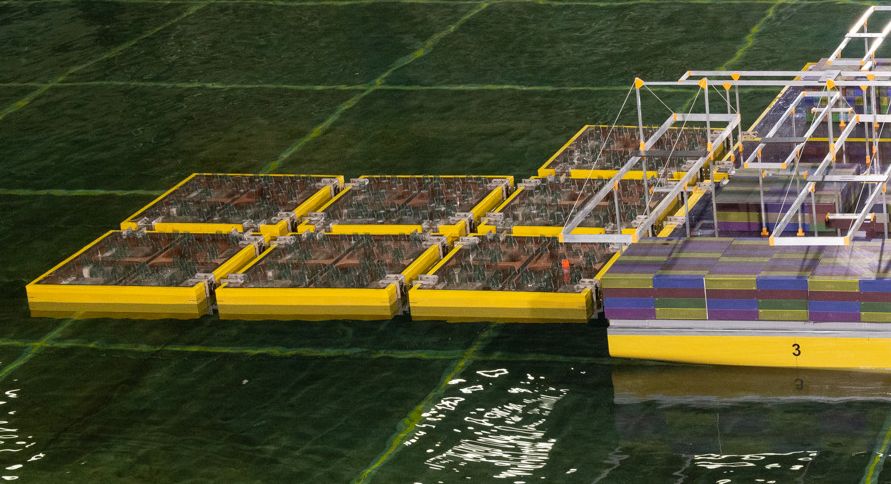

The WP8 developed concepts following the idea of Farming@Sea. Concepts for the cultivation of fish, seaweed or microalgae on the modular floater were developed. For demonstration purposes the Photobioreactor (PBR) producing microalgae was chosen. With the PBR microalgae is cultivated in translucent tubes. The bioreactor constitutes eight tubular helixes that were represented by a wrapped wire. The demonstrator comprises 448 single helixes on seven floaters representing 64 PBRs. To illustrates the successful cultivation of algae a green coated wire was the ideal solution to demonstrate the production process at model scale.

|

|

| Demonstration of the cultivation of microalgae in 448 photobioreactor helixes on seven Space@Sea modules (left). | Close up view on a helix manufactured at DST from green coated steel wire (right). |

The superstructure representing farming applications and the transport and logistics hub at sea was manufactured at DST. In strong collaboration with the NEMOS GmbH, ICE Pronav Engineering and MARIN the connectors, floaters and other superstructure were designed and directly manufactured at the testing facility where the demonstration took place.

For more information and recent news please visit: https://www.spaceatsea-project.eu/about-space-at-sea

Duration: 3 years (until November 2020)

Contact persons at DST:

Dipl.-Ing. Jens Ley

Gerrit Assbrock M.Sc.

The Space@Sea project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 774253.